3D Printing Slicing Software

ADAXIS was launched at the beginning of 2021 by Henri Bernard, Guénolé Bras, Emil Johansson and Vasan Churchill, following years of applied research into using industrial robotics for advanced manufacturing at ESTIA and RISE Research Institutes of Sweden.

The team first met during a collaborative research project where they found a shared frustration with the time-consuming and complex task of programming industrial robots for 3D printing. One year later, ADAXIS was formed to solve this problem by bringing a new intuitive and powerful robot programming software for controlling robot arm 3d printers to market.

Today, ADAXIS is a multi-national team of innovators based between the two cities of Bidart, France, and Gothenburg, Sweden. We help world-leading companies in automotive, aerospace, manufacturing, construction, and interior design to create new innovative and sustainable products.

AdaOne

AdaOne is a powerful and intuitive software for robotic additive manufacturing of metals, plastics, composites and concrete. The software platform covers every aspect needed to go from idea to finished part. Path planning of robotics has never been easier

Key features

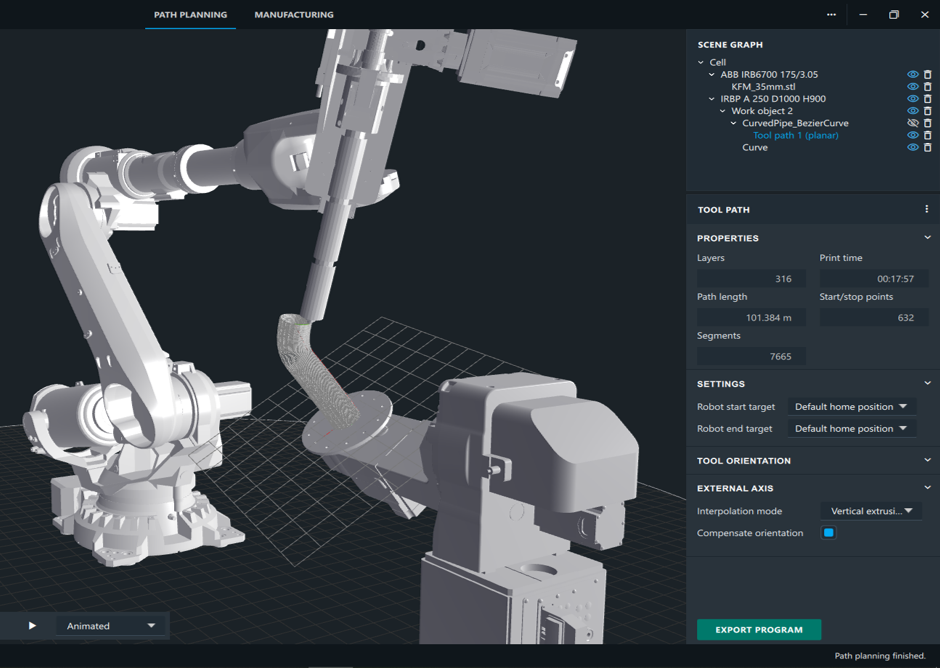

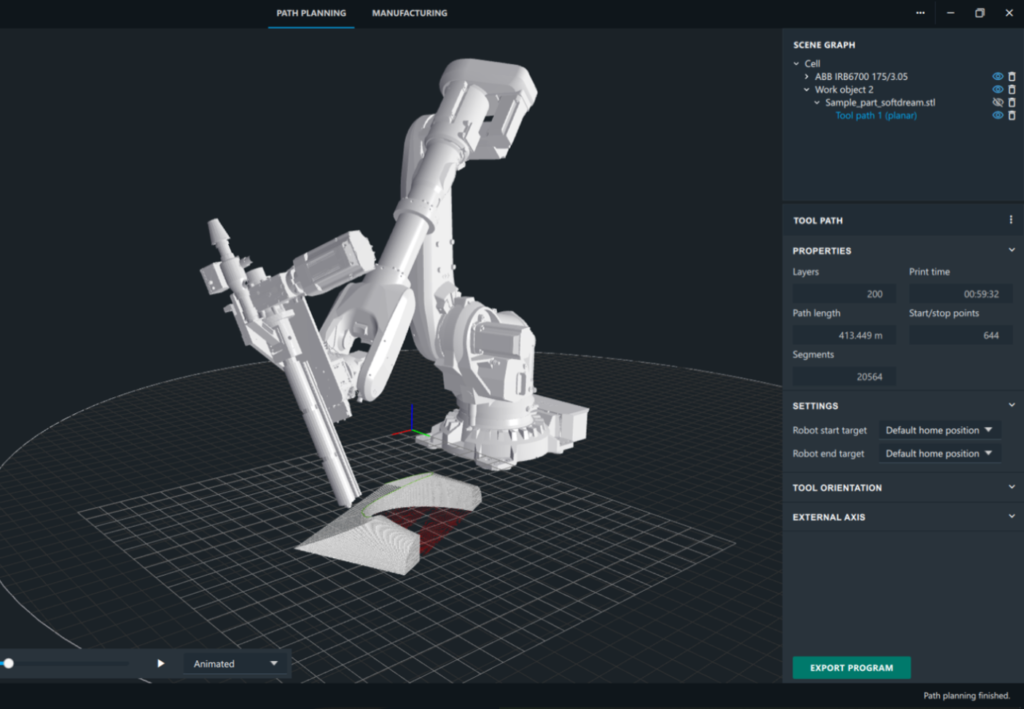

Robot simulation

External axis support

Customize robot programs

Import and simulate ABB, KUKA and Fanuc robot arms and positioners. Turns any brand into a robot arm 3D printer

Interpolation strategies for 2-axis positioners integrated into the robot programming software

Customize robot programs in ABB Rapid, KUKA KRL, FANUC LS, or G-code, turning any robot arm into a 3D printer

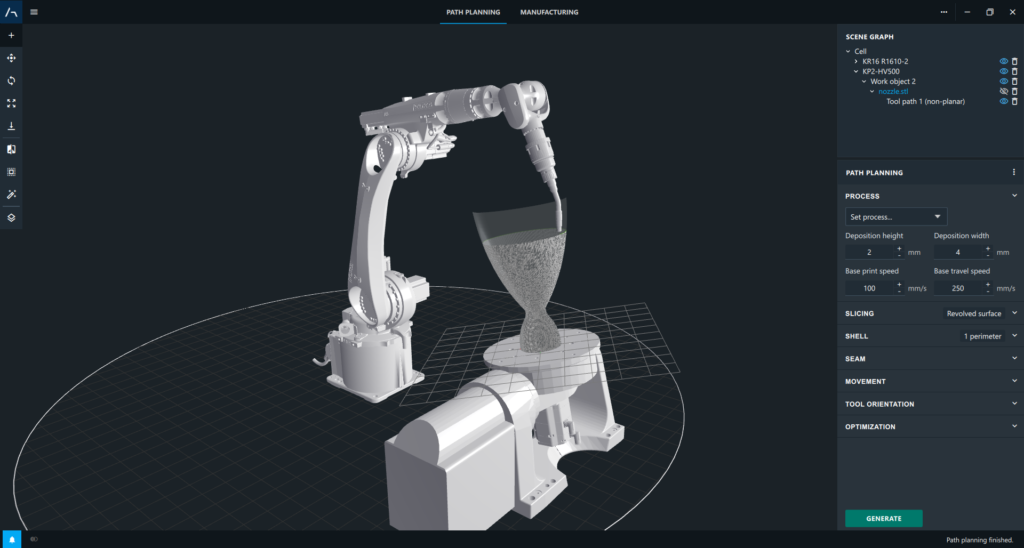

Multi-axis path planning

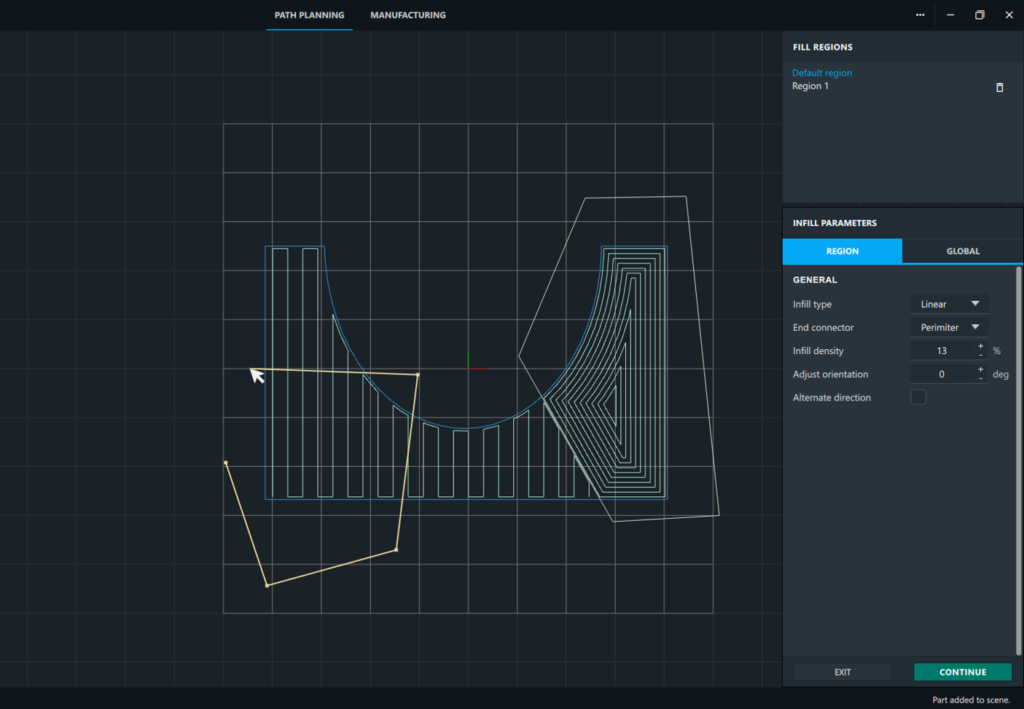

Plan paths by region

Adapt tool orientation

Planar slicing, angled slicing, planar slicing along b-spline, radial slicing, conical slicing, revolved surface slicing etc, all of this can be achieved via the 3D printing slicing software making it one of the best tools for path planning in robotics

Optimize printing of a part, e.g. for performance or weight, by defining zones with custom path planning in robotics setings

Generate and optimize tool orientation based on part geometry.

Flexible 3D model support

Mesh operations

Collision detection

Support for common mesh based formats (STL, OBJ, 3MF, glTF) and boundary representation format (STEP).

Boolean operations, isotropic and non-isotropic offsetting, and automatic repair.

Detection of collisions between static and dynamic objects during printing is automatic in the robot programming software

Perform advanced path planning in robotics with ease

Create optimized robot programs for your manufacturing cell.

Use existing robots and material deposition units and configure a custom post processor based on your needs to plan your prints with this capable 3D printing slicing software

- ABB, KUKA and FANUC support

- Create custom post processors

- Define events, I/Os and external axes

- Export arc movements thus reducing computing size of the path planning in robotics

- Export layers separately