Advanced Laser 3D Printing Cells with Meltio Technology

ADDICT3D delivers state-of-the-art laser 3D printing cells powered by the Meltio DED (Directed Energy Deposition) laser head. Whether you’re looking for a fully customized solution or a ready-to-deploy containerized system, we provide the tools to redefine your manufacturing capabilities.

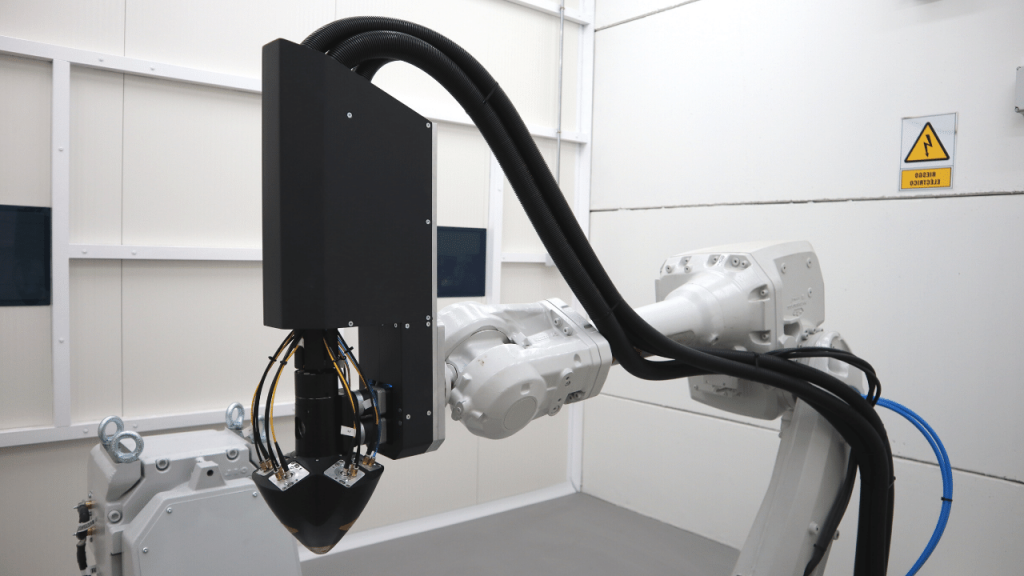

Custom-Designed Printing Cells

Tailored to your specific needs, we build advanced robotic 3D printing cells that seamlessly integrate with your production environment. From compact designs for tight spaces to larger systems for complex manufacturing, our solutions prioritize precision, efficiency, and reliability.

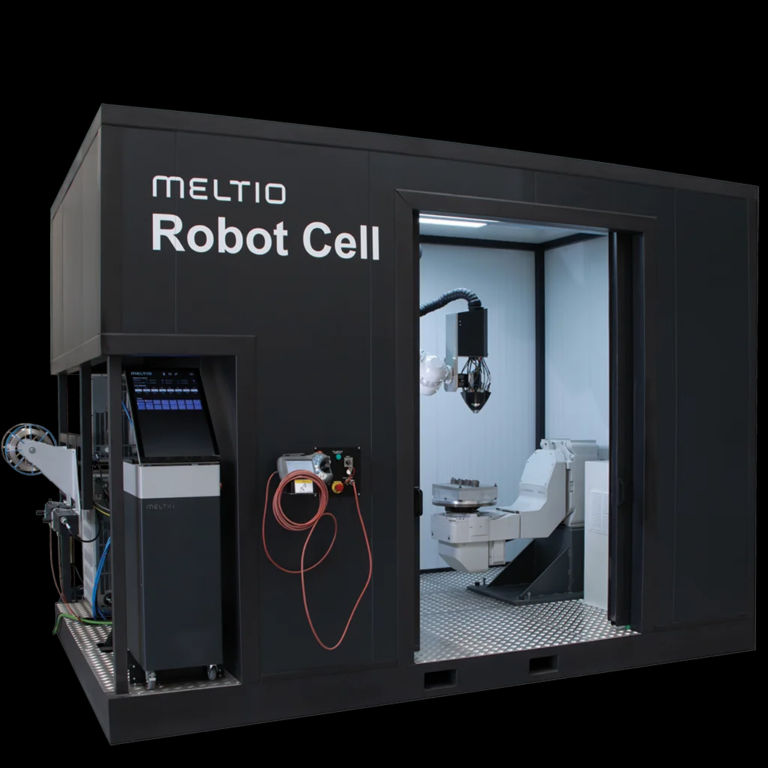

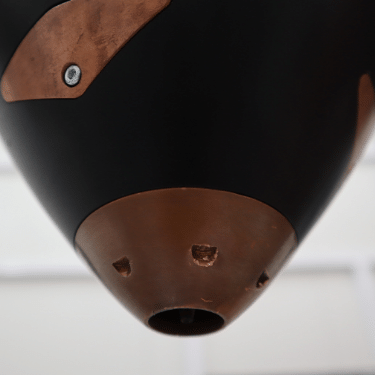

Atratus Printing Cells

For businesses requiring peak design and versatility, our container-style Atratus 3D printing cells offer a plug-and-play solution. This sleek unit bring cutting-edge additive manufacturing capabilities directly to your site, enabling rapid deployment and flexible production.

Meltio’s Standard Container Cell Installation

ADDICT3D also provides installation and integration services for Meltio’s standard container cells. Our expertise ensures a smooth implementation process, so you can start leveraging Meltio’s advanced technology with minimal setup time.

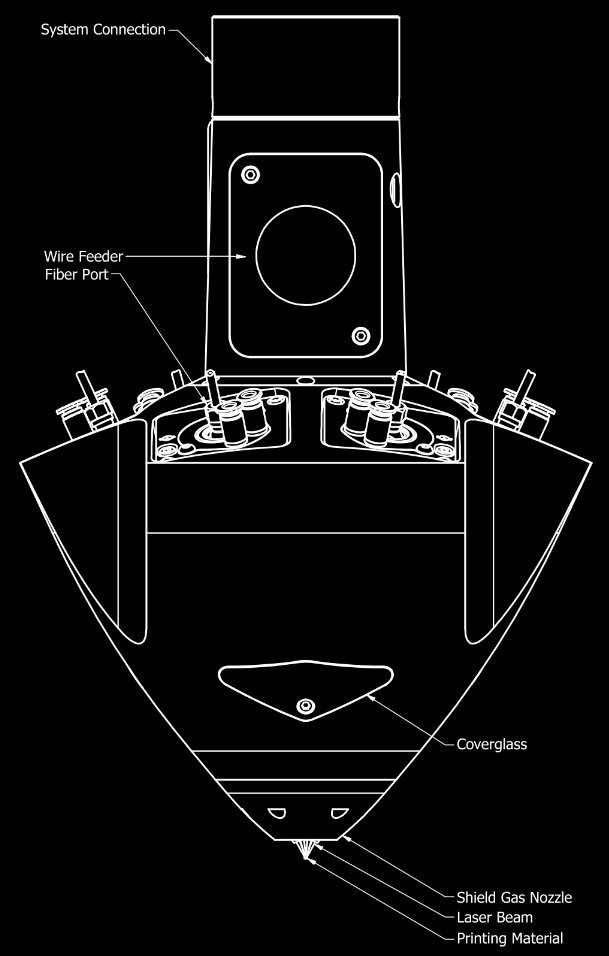

Why Meltio DED Technology?

The Meltio DED laser head stands out for its ability to manufacture high-quality metal parts with speed and precision. Its advantages include:

Material Versatility: Print with a variety of metals for diverse applications.

Efficiency: Minimized waste and optimized material usage.

Scalability: Perfect for both prototyping and large-scale production.

High Complexity

Create highly complex parts with infinite degrees of freedom.

Retrofitting

Provide new capability to any robot arm by turning it into a robotic metal printing 3D system.

Part Repair

Cost-effective component repair, part augmentation and feature addition.

Large Size

No inherent constraints when the working envelope is only limited by the size of the robot metal AM motion system.

Open Materials Platform with Wire DED

Mild Steels

Cheap and ductile, with unparalleled machinability and weldability.

Carbon Steels

High impact strength, retain hardness at high temperatures.

Titanium

High strength to weight ratio and corrosion resistance.

Nickel

High versatility, outstanding heat and corrosion resistance.

Stainless Steels

Excellent strength and corrosion resistance.

Copper

Under development

Upgrades and Accessories

Hot Wire

Programmable power supply that preheats the material to increase the deposition rate of this Wire DED system

Dual Wire

This option allows to 3D print two wire materials sequentially with very quick wire switches.

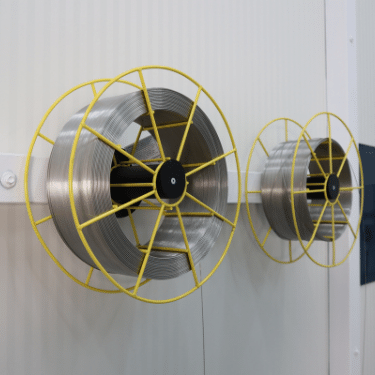

External Wire Drum

Draw from an external wire source. Drums from 100kg may be used for convenience.

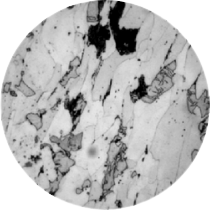

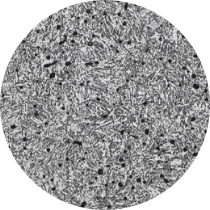

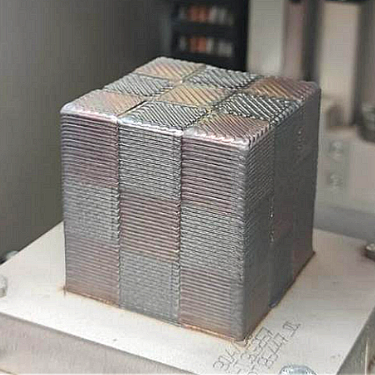

Excellent Mechanical Properties

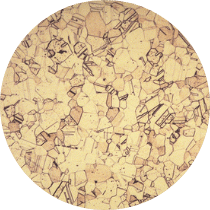

Meltio’s compact heat affected zone process achieves exceptional mechanics, decreased thermal stress and near isotropic properties, exceeding casting and forging material properties.

Part density

Layer Height

Post Processing

Part density

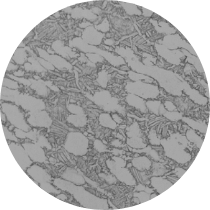

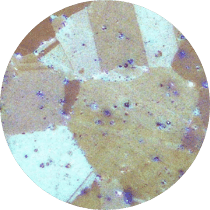

Consistent 99.998% densification

Meltio’s WP-LMD produces fully dense parts with superior microstructure. Exceeding the casting and forging properties, and in certain cases, matching up to wrought material properties.

Layer Height

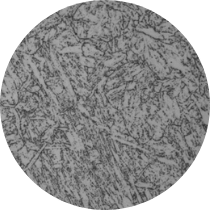

From 0.3 to 1.2mm layer heights

Meltio’s process allow for an exceptional balance between print speed and surface roughness. Under some conditions, Meltio’s surface roughness using wire can outperform those produced with powder based processes.

Post Processing

Post-process or use as printed

For many applications printed in high-resolution little to no post treatment is necessary. Near net shapes can be post-processed using heat, bead blasting, polishing, brushing or machining.

High Power

Laser power of 1.2kW and optional hot wire system for increased deposition rates.

Extremely Efficient

The wire deposition utilizes 100% of the material and the heat input is kept extremely low making this system a very cost effective 3D metal printing technology