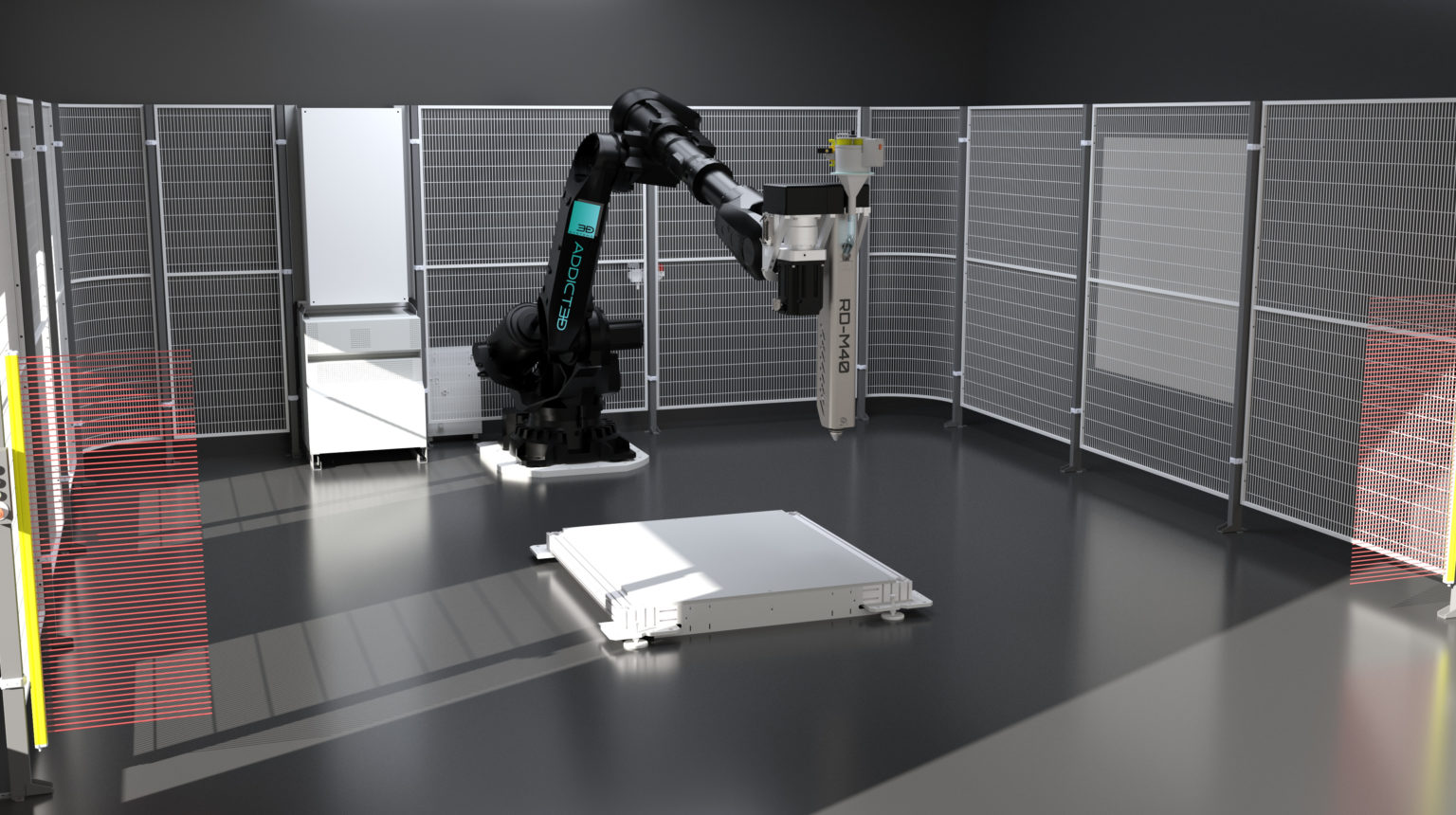

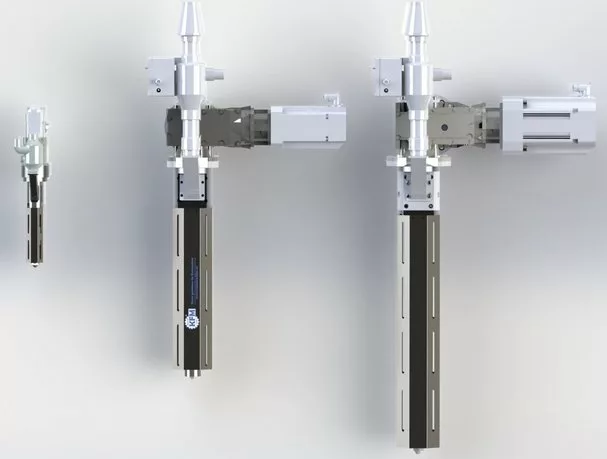

The close connection that ADDICT3D has Spectrum Technology AB, the Swedish automation provider, means that we build from years of experience with Large Scale Additive Manufacturing withing FGF 3D printing specifically , and more recently also within wire DED (laser deposition using welding wire).

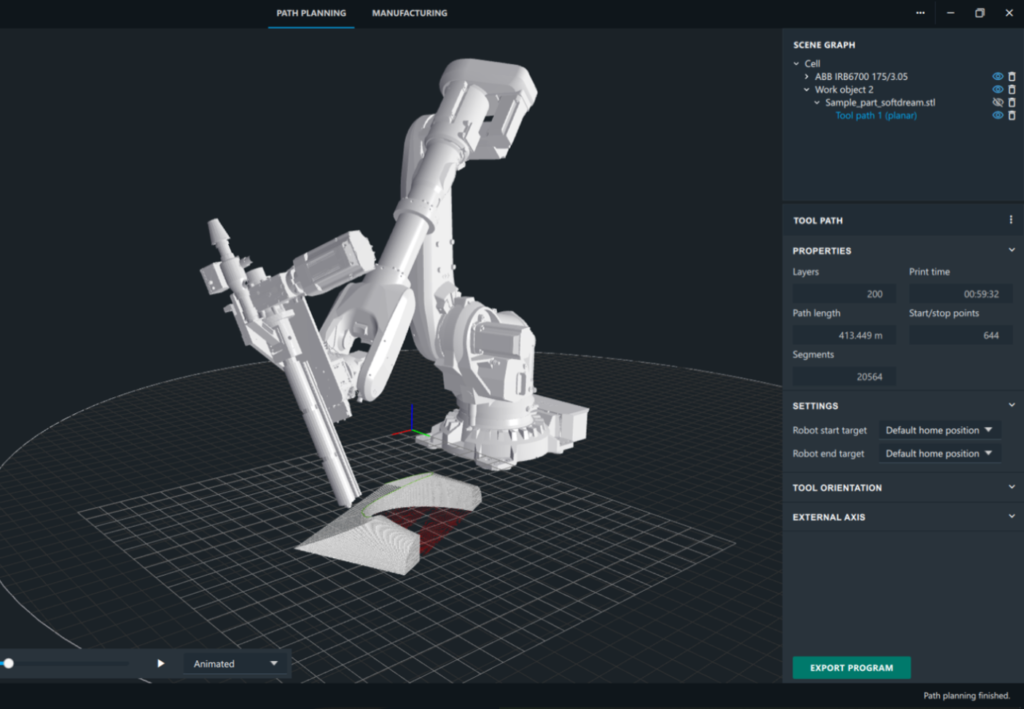

Six years ago, an EU project was formed named Softdream with the aim to increase possibilities of slicing for robotic cells. The project was a huge success and was turned into the now well known company Adaxis. It is well-known in the industry that complex slicing is difficult, and needed to produce certain parts where support material is otherwise a limitation for LSAM.

As a distributor of Adaxis software, Adaone, we work closely and monitor and assist in development and testing of new strategies to the benefit of our customer. Whilst being an open platform, we tailor the cells to benefit to the max from the capabilities of Adaone.

Slicing strategies range from the simpler version like Cartesian and angled, to geodesic, sweep based and even non-planar strategies. Coupled with rotational tables or even positioners, your capabilities increase in way difficult to imagine. On top of this, ABBs 3DP package adds even more flexibility, functions of which we are able to get you up and running with in no time, laying out complex patterns with the robot controlled pellet extruder.

For ABB, Kuka, Fanuc and Yaskawa robots there are possibilities to add post processing steps in your code for greater flexibility. wit