What is Meltio?

Meltio has an interesting background story. Brian Matthews the current CTO of Meltio and a nuclear physicist, worked in the nuclear industry for 20 years. He wanted imagined about the possibility of radically changing the energy production by taking small and micro nuclear reactor concept further and to a stage where entire reactor systems could be built using 3D printing technology. Brian spent several years exploring and studying this idea and ultimately developed a DED 3D printing technology which he commercialized through his startup, AddiTec.

In order to expand the industrial applications, AddiTec decided to explore partners who can scale up its technology. This is how Brian decided to collaborate with Sicnova, a Spanish company with over 15 years of 3D printing and manufacturing/distribution experience. And with this newfound partner, both organizations joined forces to form Meltio, a new entity. Today, he acts as the Chief Technology Officer at Meltio.

State of Metal 3D Printing Market

A recent report from IDTechEx estimated that the metal 3D printing market will reach $18.5 billion in the next ten years. The past two years were impacted by the pandemic and the market saw many industries reducing their initiatives into additive manufacturing leading to a slower AM Adoption. But the market is expected to recover soon. The report states that as the activity gradually recovers, the metal 3D printing market will see an estimated annual growth rate of 18.8 percent.

DED 3D Printing

DED, or Directed Energy Deposition, is a metal 3D printing technology that uses metal wire or powder that is melted by a focused heat source such as a laser, electron beam, or even an arc, and then deposited layer by layer onto a build platform. Typically, this technology is used to repair and rebuild damaged components but is widely used to build objects from scratch as well.

DED 3D printing has several advantages, including multi-material capabilities, hybrid manufacturing capabilities, less material waste when compared to power-bed fusion technologies, the ability to create large parts, and it uses relatively low heat input when using powder and does not require a vacuum environment as an energy source.

Wire vs Powder-based Technologies

In metal 3D printing, metals are most commonly used in a wire form or powder form. The feedstock used in a metal 3D printing process has a significant impact on material cost, print speed and resolution, quality, and safety. As a result, selection becomes a critical factor.

- In terms of material costs, high-quality metal powders are very expensive to produce and can cost anywhere from twice to three times the price of metal wires.

- Wire-based technologies print at much faster speeds than powder bed fusion technologies. It is possible to deposit 10 Kg/hour through wire-based DED technologies.

- The majority of users are aware of the quality and safety precautions required for powder bed fusion processes. It is necessary for an operator to wear specific suits, and the environment must be clean, cool, and dry. Other costly equipment is required to extract the printed part from the unfused powder. On the other hand, wire-based technologies do not require such elaborate safeguards.

Market applications

Naval propeller 3D printed on Meltio Engine Robot/Meltio

Wire-based DED technologies have a wide range of applications in mission-critical industries such as aerospace, automotive, healthcare, energy, defense, tooling, and more for parts such as engines, turbines, blisk, propeller, mining drill bit, implants, and more.

Products

Meltio offers three metal 3D printing solutions: the Meltio M450 Metal 3D printer, the Meltio Engine with CNC integration, and the Meltio Engine with Robot integration.

Meltio M450

The Meltio M450 is a metal 3D printer designed for industry without the need for industrial infrastructure; affordable, dependable, safe, and simple to use. It is ideal for small to medium-sized part fabrication and research into multi-metal 3D printing.

Meltio’s multi-metal DED 3D printer creates highly dense metal parts in a single step process.

It can also be upgraded with accessories to improve performance and overall operational experience. Users can add a programmable power supply, which preheats the material to increase the deposition rate, or a dual wire option, which allows you to 3D print two wire materials sequentially with very quick wire switches, and even add a station, which is a sturdy wheeled table made of stainless steel and aluminium with drawers that can hold all of the tools at hand.

Meltio Engine with CNC Integration

The Meltio engine with CNC integration allows users to turn any machine tool into a hybrid manufacturing system with the printing size equivalent to the size of the machine (without the head volume). The Meltio Engine is an excellent CNC companion for near net shape manufacturing, repair, and feature addition. It is the most cost-effective hybrid manufacturing solution, compatible with almost any CNC machine on the market. Metal 3D printing and machining of complex geometries can be accomplished in a single process step.

The CNC integration unit comes with two upgrades: a dual wire add-on and external wire drums that carry 100kgs of wire.

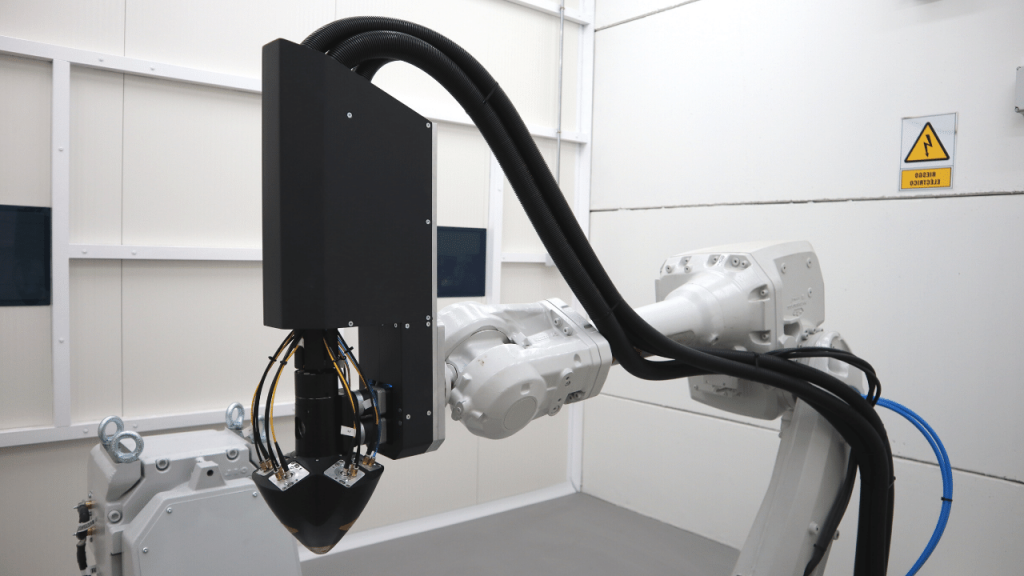

Meltio Engine with Robot Integration

The Meltio engine with Robot integration can transform a robot arm into a metal 3D printing system. This also comes with no specific size limitation and will depend on the volume the user wants. This platform is ideal for large and complex 3D printing, repair, cladding, and feature addition.

The Robot integration comes with four upgrades like the hot wire, dual wire, and external wire drum, and the addition of a powder feeder, which is required for 3D printing from powder feedstock, unlocks on the fly metal alloying.

The powder is developed focused on research and universities

Technical Specifications

The following are the technical specifications for Meltio’s additive manufacturing solutions.

| Specifications | Meltio M450 | Meltio Engine + CNC | Meltio Engine + Robot |

| Dimensions (W*D*H) | 560*600*1400mm | 390*700*1025mm | 390*650*1000mm |

| Print Envelope (X*Y*Z) | 150*170*425mm | inherent to motion system | inherent to motion system |

| Weight | 250kg (head weighs 20 kg) | 142kg (head weighs 20 kg) | 142kg (head weighs 20 kg) |

| Laser Power | 1200W | 1200W | 1200W |

| Laser Type | multiple 200W direct diode lasers | multiple 200W direct diode lasers | multiple 200W direct diode lasers |

| Laser Wavelength | 976nm | 976nm | 976nm |

| Process Control | closed-loop, laser and wire modulation | closed-loop, laser and wire modulation | closed-loop, laser and wire modulation |

| Power Input | 208/230V single phase or 400V three phase | 208/230V single phase or 400V three phase | 208/230V single phase or 400V three phase |

| Power Consumption | 2-5kW peak depending on selected options | 2-5kW peak depending on selected options | 2-5kW peak depending on selected options |

| Wire Feeds | up to 2 x K300 spools | from one K300 spool up to two external wire drums | from one K300 spool up to two external wire drums |

| Wire Feedstock | 0.8-1.2mm wire diameter | 0.8-1.2mm wire diameter | 0.8-1.2mm wire diameter |

| Cooling | active water-cooled chiller included | active water-cooled chiller included | active water-cooled chiller included |

| Powder Feeds | – | – | external plug and play powder feeders |

| Powder Feedstock | – | – | 45 to 90um particle size |

Concluding Remarks

Meltio offers a unique hybrid solution that combines the capabilities of Additive and the ease of Subtractive. In a research paper titled ‘Hybrid Additive Manufacturing Technologies – An Analysis Regarding Potentials and Applications” published in Science Direct, the authors concluded that the combination of additive and subtractive manufacturing and integrating additive processes into the production chain offers a high potential for industrial use because many of additive’s disadvantages can be compensated.

It is self-evident that the adoption of hybrid systems will grow rapidly as it is much closer to the traditional technologies and delivers greater benefits that standalone additive systems.