In a world where innovation knows no bounds, one collaboration has stood out for its remarkable contribution to the 3D printing industry. Discover how the dynamic partnership between Adaxis and ADDICT3D, an extension of Spectrum Technology, is transforming the realm of large-scale 3D printing, with a special focus on slicing software and robotics.

Exploring the Horizon EU Project

Several years ago, the Horizon EU Project identified a significant challenge within the 3D printing landscape. Although 3D printing had already revolutionized prototyping and small-to-medium component production, it had not yet made its mark on larger industrial applications. This led to the critical question: How could 3D printing become a game-changer in sectors demanding massive, intricate, and high-quality components?

Enter the EIT Manufacturing SoftDream project, a visionary initiative aimed at developing cutting-edge software tools for hybrid robot-based 3D printing on an industrial scale. The primary goal was to create a versatile, user-friendly application capable of seamless communication with various industrial robot brands. This ambitious project included the launch of a startup in 2021, with players like Volkswagen, Aerospace Valley and ESTI to name a few.

The collaboration brought together experts from diverse fields, with Adaxis and ADDICT3D at its forefront. They embarked on a journey characterized by joint efforts and collaborative learning, pooling their expertise to drive innovation in 3D printing, slicing software, and robotics.

From Dream to Reality: Adaxis Leads the Way

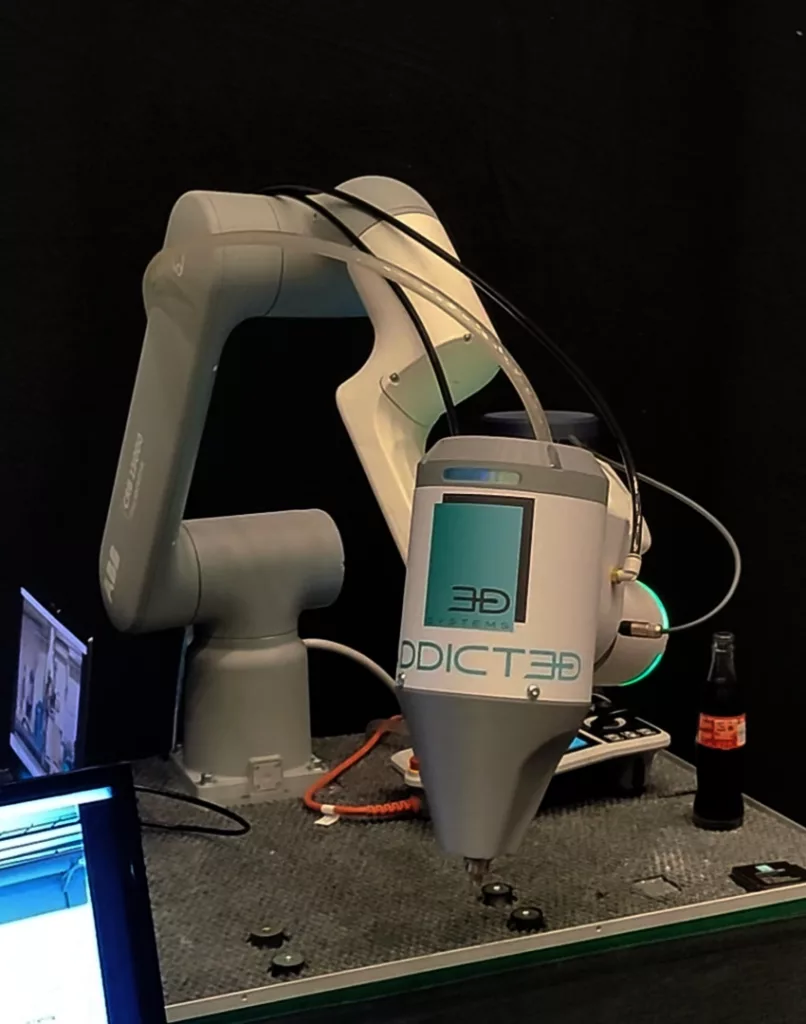

Fast forward to today, and SoftDream has evolved into Adaxis, a pioneering company in the 3D printing domain. Their ground-breaking slicing software, AdaOne, has become the linchpin of the large-scale 3D printing revolution. But the story doesn’t end there. ADDICT3D has emerged as a key player in this dynamic landscape.

With a dedicated team of 15 employees spanning Sweden and France, Adaxis has secured a substantial market share. Their competitive advantage lies in their profound understanding of industry needs and their seamless integration with a wide range of robot brands, including ABB, KUKA, Fanuc, and Yaskawa.

Mastering Slicing Strategies for 3D Printing

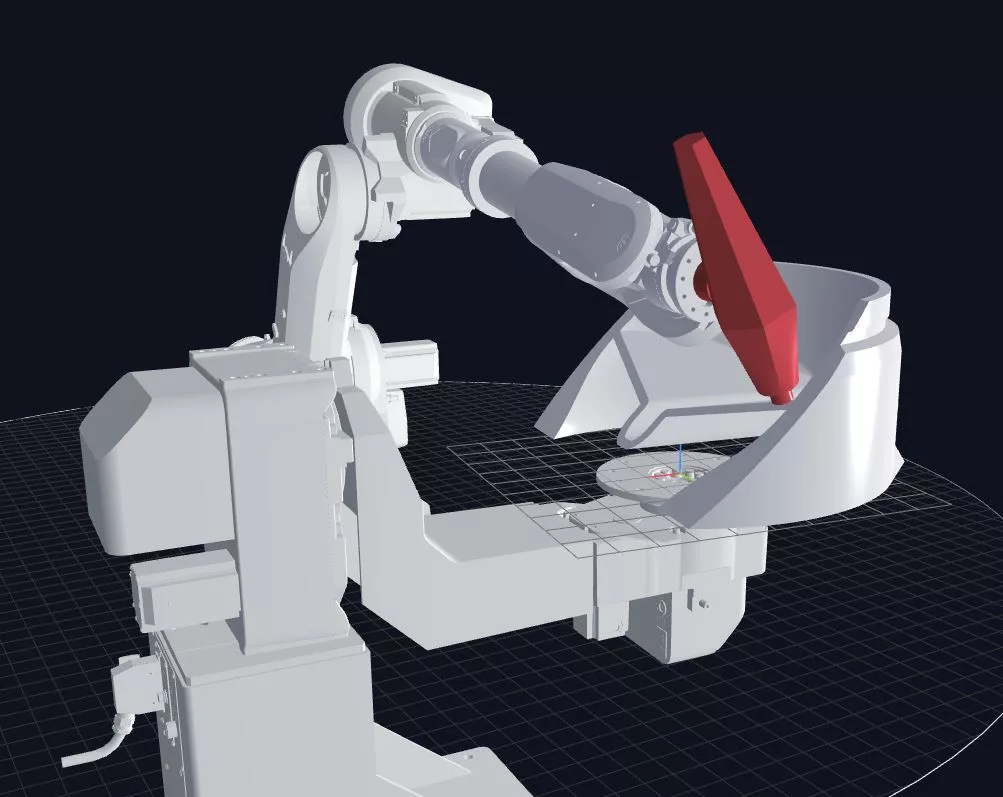

One of the collaboration’s standout achievements is the development of diverse slicing strategies. From the elegant sweep to precise planar along the curve and efficient conical slicing, Adaxis, with much input from Jonas at ADDICT3D, have refined their slicing software to handle complex geometries seamlessly. These systems boast multiple axes, mirroring the dexterity of robotics in the 3D printing process.

Why It Matters: The Intersection of 3D Printing, Slicing Software, and Robotics

So, why should the world take notice of this collaboration? The answer lies in the boundless potential for innovation. As Adaxis and ADDICT3D continue to push the boundaries of large-scale 3D printing, industries like automotive, construction, and aerospace can anticipate cutting-edge solutions. Components once considered too large or intricate for 3D printing are now within reach, offering cost-effective, efficient, and sustainable manufacturing processes.

In conclusion, the collaboration between Adaxis and ADDICT3D is a testament to the transformative power of innovation and collaboration at the intersection of 3D printing, slicing software, and robotics. As these companies redefine the possibilities in the world of large-scale 3D printing, they are not just transforming industries—they are shaping the future of manufacturing, one layer at a time. Keep a close eye on this dynamic duo as they continue to revolutionize the 3D printing landscape with their cutting-edge technologies.